Selecting the Right Blade for Composite Decking

Choosing the right blade will help you to achieve accurate, clean cuts and extend the life of your gear when it comes to cutting composite decks. Being a specialist in this field, I can confirm the need of knowing the special features of composite materials and precisely how they interact with various types of saw blades.

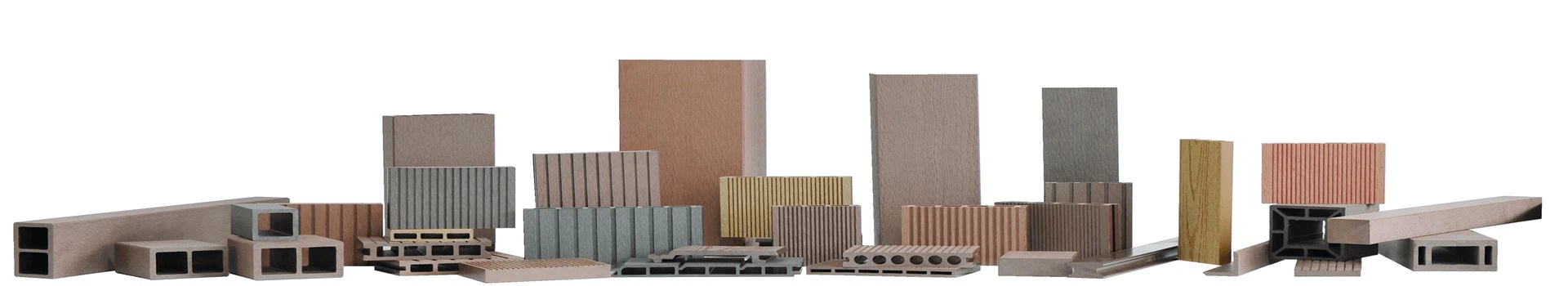

Made from a combination of plastic and wood fibers, composite outdoor decking calls for a blade that can effectively handle both parts. Carbide-tipped teeth are the perfect blade for cutting composite outdoor decks as they are designed to remain sharp longer and provide a more smooth cut. Moreover, a high tooth matter blade is excellent as it improves coating and lowers breaking risk.

Right here are some crucial specs to take into consideration when picking a blade:

| Spec | Suggested Value |

|---|---|

| Product | Carbide-tipped |

| Tooth Count | 40-80 teeth |

| Blade Size | 7-1/4" to 12" |

| Kerf Width | Slim kerf (0.090" - 0.145") |

| Hook Angle | 5 ° |

until 15 degrees Celsius. Based on my experience, blades specifically made for cutting composite materials often perform significantly better than general-purpose wood-cutting blades. Usually with a bespoke triple-chip grind (TCG), these specialist blades revolve between a trapezoidal tooth and a flat-top tooth. This arrangement assures a better cut and helps to reduce burring.

Furthermore by lowering material waste and frequency of blade substitutions, a high-grade blade may save time and money over time. Leading brand names like Diablo, Freud, and DeWalt manufacture blades fit for composite outdoor decking appropriate. These producers create blades specifically designed to provide best sturdiness and efficiency while handling composite goods.

Functions to Seek in a Composite Decking Blade

When selecting a blade for cutting composite decking, several essential features can substantially impact the top quality and performance of your cuts. Below are the essential elements to take into consideration:

1. Blade Product: Go with a blade that is developed specifically for reducing composite materials. Tungsten carbide or carbide-tipped blades are optimal as a result of their longevity and resistance to use.

2. Variety of Teeth: Seek a blade with a greater tooth matter, usually between 40 to 80 teeth. More teeth result in smoother cuts and minimize the possibility of chipping or splintering.

3. Blade Design: Select a fine-toothed blade with an alternate top bevel (ATB) or triple-chip grind (TCG) style. These arrangements work in reducing through composite materials cleanly.

4. Blade Dimension: Make certain the blade dimension matches your cutting device and the thickness of the composite outdoor decking material. The majority of round saws and miter saws accept blades ranging from 7 1/4 inches to 12 inches in diameter.

5. Anti-Vibration Features: Blades with built-in anti-vibration slots or dampening features help decrease sound and vibrations during procedure, enhancing both security and convenience.

6. Toughness and Longevity: Buy a blade known for its durability. Carbide-tipped blades, while slightly a lot more pricey, offer extended usage without regular substitutes.

7. Compatibility: Make certain compatibility in between the blade and your cutting device. Check the arbor dimension and installing technique to avoid any type of concerns during installment.

By focusing on these features, you can make best use of the efficiency of your blade and attain accurate cuts when working with composite outdoor decking products.

Top Blade Brands for Reducing Composite Decking

When cutting composite decking, choosing the right blade is essential to get precise and clean cuts. Many top-notch brand names are well-known for their blades especially made for composite decking, which show great quality. Here I will list some of the top brands along with their unique purposes.

Diablo

Premium cutting tools are why Diablo is so well-known; their blades for composite decking are no exception. Their Diablo TrexBlade's ultra-fine finish and durability help to explain its great popularity. The revised triple chip work (MTCG) tooth design of this blade ensures neat cuts and reduces material melting risk.

Freud

Based on name in the field, Freud offers blades with precision and durability. One very interesting option for cutting composite materials is the Freud D1296N. Its non-stick Perma-SHIELD coating reduces drag and resin buildup, therefore improving the efficiency and lifetime of the blade.

Makita

Makita provides composite decking among other uses for high-performance blades meant for a range of applications. With an ATAF (alternative top and alternate face) teeth arrangement, the Makita A-93681 blade reduces product chipping while nevertheless ensuring accurate, clean cuts.

DEWALT

One other top brand name with great blades for composite decking is DEWALT. Their DEWALT DW3128 is recommended for accuracy and lifespan. It's a good choice for both professionals and do-it-yourself enthusiasts as it features a narrow kerf design that allows considerably less product waste and smoother cuts.

Tips for Effective and Safe Reducing of Composite Decking

| Pointer | Details |

|---|---|

| Select the Right Blade | Carbide-tipped, high tooth count (40-60 teeth) |

| Safeguard the Decking Properly | Clamp or attach safely to avoid movement |

| Use Security Equipment | Shatterproof glass, gloves, dirt mask |

| Keep a Steady Reducing Rate | Stable, regulated speed to avoid splintering |

| Maintain the Workplace Tidy | Clear particles and dirt consistently |

| Examine and Maintain Your Devices | Examine saw and blade for good condition |