Make-up of Composite Decking: Secret Materials

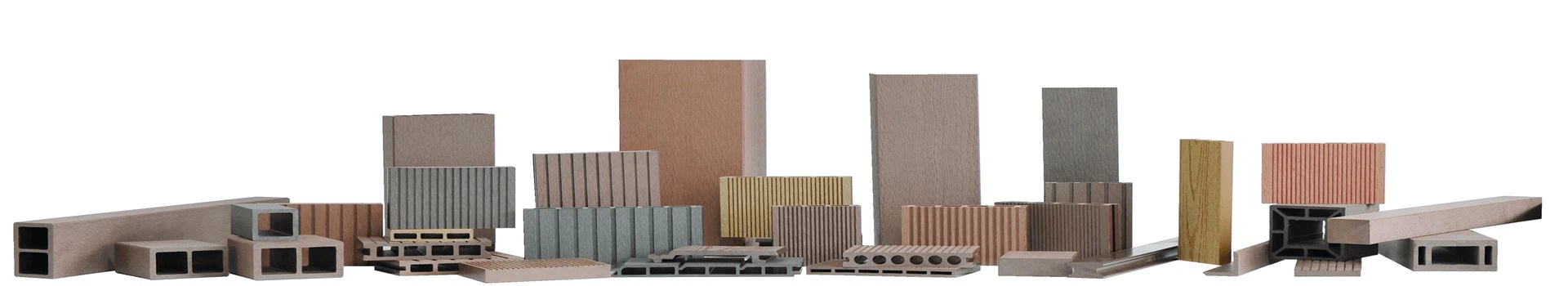

Throughout the years working with decking goods, I have discovered that understanding the composition of composite outdoor decking is essential to making wise choices. Modern technology called compound decking was created to solve many of the issues associated with traditional wood outdoor decking. It is composed of a variety of components, each of which contributes unique residential or commercial qualities to the final product. The chemicals, plastic, and wood fibers are the main components of composite outdoor decking.

Wood Fibers

An essential component of composite decking is wood fibers. There are other sources of these fibers, such as reclaimed wood and sawdust. Timber fibers contribute to the composite product's durability and natural beauty by mimicking the appearance of all-natural wood and providing architectural stability.

Plastic

The second important component of composite decking is plastic. Recycled polypropylene or polyethylene are frequently used to make it. The plastic component helps to keep the wood's fibers together, giving it resistance against rot, moisture, and insect damage. Because of this combination, composite decking is far more resilient to harsh environmental conditions than traditional timber.

Ingredients

Various ingredients are consisted of in the composite decking blend to improve performance. These additives can include:

| Additive | Function |

|---|---|

| UV Stabilizers | Shield the outdoor decking from fading due to sunshine direct exposure. |

| Colorants | Offer a vast array of color alternatives to match visual choices. |

| Stabilizers | Enhance overall sturdiness and durability of the decking. |

| Lubricants | Improve the production process by lowering rubbing throughout extrusion. |

The combination of plastic, additives, and wood fibers results in a product that is not only aesthetically pleasing but also incredibly durable and low-maintenance. You can appreciate the creative design that goes into creating composite outdoor decking and understand why it has become a popular choice for both home builders and homeowners by being aware of these essential components.

Production Process of Compound Decking

The process of manufacturing composite outdoor decking involves multiple crucial phases that contribute to the durability and aesthetic appeal of the final product. Recycled wood fibers and plastic are the main materials used; they are thoroughly combined to create the desired buildings.

The wood fibers are initially extracted from a variety of materials, including sawdust, wood chips, and other waste products from the forestry industry. After that, these fibers are treated and cleaned to ensure they are free of contaminants. Concurrently, the plastic components-which are typically obtained from recycled polypropylene or polyethylene-are cleaned and shred into smaller bits.

The plastic and wood fibers are combined in precisely the right amounts to produce a homogenous mixture in the following stage. The mixture is then directly fed into an extruder, a piece of specialized machinery that warms and combines the components. The heat melts the plastic, encasing the wood fibers and creating a strong connection between the two items. The composite product is further shaped by the extruder into a consistent shape, which is then cooled and reduced to the required sizes.

To improve the performance of the composite decking, several substances may be added during the extrusion process. These components may include colorants that provide a range of visual options and UV inhibitors that protect the outdoor decking from sun damage. Additionally, bonding agents and stabilizers are typically added to improve the material's architectural integrity and resilience to moisture and pest damage.

The composite decking boards go through a final process after being extruded and cooled. In order to replicate the look of genuine wood, this may entail texturing the surface and adding sealants or protective finishes to increase durability. Throughout the manufacturing process, quality control procedures are used to ensure that every board meets exacting standards for durability, toughness, and appearance.

The final product is an excellent, low-maintenance outdoor decking material that combines the best qualities of plastic and wood. Composite outdoor decking provides a durable and environmentally responsible alternative to traditional timber decking by utilizing recycled materials and cutting-edge production techniques.