What is WPC Decking and Just How is it Made?

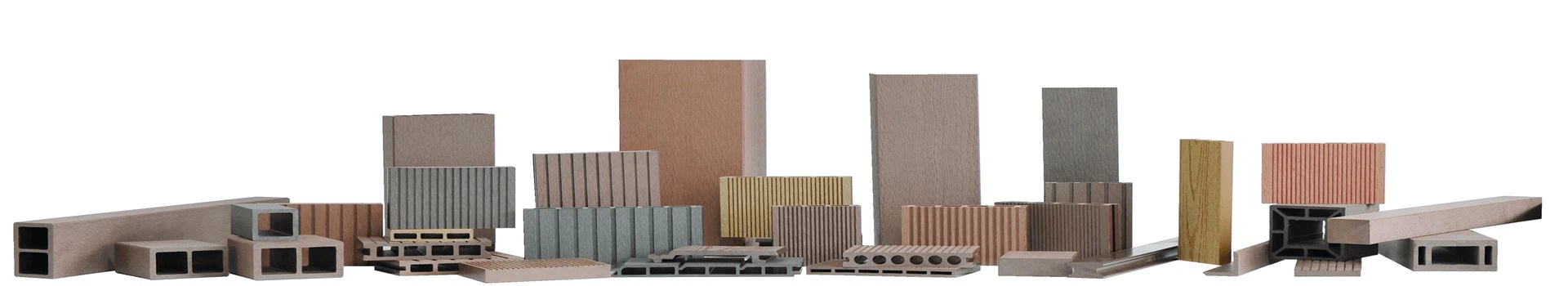

As an expert in the field, I can inform you that WPC decking, or wood-plastic composite outdoor decking, is a state-of-the-art material that combines the durability and low maintenance of plastic with the aesthetic appeal of real wood. The procedure used to create WPC decking combines recycled polyethylene, polyvinyl chloride (PVC), or polypropylene with natural wood fibers, or wood flour.

The manufacturing process entails several steps:

| Tip | Description |

|---|---|

| 1. Raw Product Prep Work | Timber fibers or flour and plastic materials are gathered and processed. The wood fibers are dried to eliminate wetness, making certain much better adhesion with plastic. |

| 2. Blending | The dried out timber fibers and plastic materials are blended together with numerous additives such as colorants, UV stabilizers, and bonding representatives to enhance the product's residential properties. |

| 3. Extrusion | The combined combination is heated and compelled through a mold and mildew or die to create the preferred shape and account of the outdoor decking boards. This step is crucial as it figures out the last dimensions and surface texture. |

| 4. Air conditioning and Reducing | When extruded, the continual account is cooled down, usually utilizing water baths or air cooling, and after that reduced right into conventional sizes. |

| 5. Surface Treatment | The cut boards might undergo additional surface therapies, such as embossing or sanding, to accomplish an extra all-natural wood-like look and structure. |

| 6. Quality Control | Each batch of WPC decking undergoes extensive testing to ensure it fulfills details performance standards for strength, sturdiness, and resistance to ecological variables. |

The result is a highly flexible outdoor decking material that combines the best attributes of plastic and wood. Because of its composition, WPC decking offers enhanced resistance to insect damage, rot, and decay, making it a fantastic option for outdoor spaces.

Advantages of Using WPC Outdoor Decking for Your Outdoor Areas

When considering options for outdoor decking, WPC decking has some noteworthy benefits. The durability of WPC (Timber Plastic Composite) outdoor decking is one of its main advantages. In contrast to regular wood, WPC is very resistant to pest damage, rot, and degeneration. Its composition, which blends plastic and wood fibers to create a sturdy and long-lasting product, is the source of this resilience.

The minimal maintenance requirements of WPC decking are yet another noteworthy benefit. Due to weathering and wear & tear, conventional timber decks frequently need regular staining, sealing, and repair work. However, WPC decking requires little maintenance to maintain its appearance and integrity. It usually only needs a simple routine cleaning with soap and water to stay looking brand new, saving future work and time.

Environmental benefits are also a major component of WPC decking's appeal. Since many WPC products are composed of recycled materials, they are an especially durable option. Using WPC is in line with green practices and choices because it contributes to waste reduction and the preservation of natural resources.

WPC decking mimics the look of natural wood with a variety of hues, textures, and finishes, making it visually appealing. With greater layout flexibility made possible by this series, you may achieve the desired aesthetic for your outdoor space without sacrificing effectiveness. Furthermore, WPC boards are made to resist fading, so your deck will continue to look vibrant over time.

Another crucial factor to consider is safety and security, an area where WPC outdoor decking shines. Often, the composite material is designed to be non-slip, making it a considerably safer surface in damp situations. This is especially helpful in the vicinity of swimming pools, spas, and other areas where direct exposure to water occurs frequently.

The affordability of WPC decking is the final point of differentiation. Although the initial outlay may be higher than for traditional wood, over time the lower maintenance costs and longer lifespan make it a more financially sound choice. Longevity and less maintenance translate into lower costs for replacements and repairs, increasing the overall return on your investment.