Choosing the Right Saw Blade for Composite Decking

A perfect cut and preservation of the material depend on selecting the correct saw blade for composite decking. Choosing a blade specifically for composite decking guarantees long-lasting performance and improves the general quality of your project as its particular mix of wood fibers and plastic calls for it.

Overview

Examining many saw blade types fit for composite decking, this page explores tooth count, material composition, and suggested brands. Knowing which saw blade you use for composite decking not only improves your work but also safeguards your equipment and material investment.

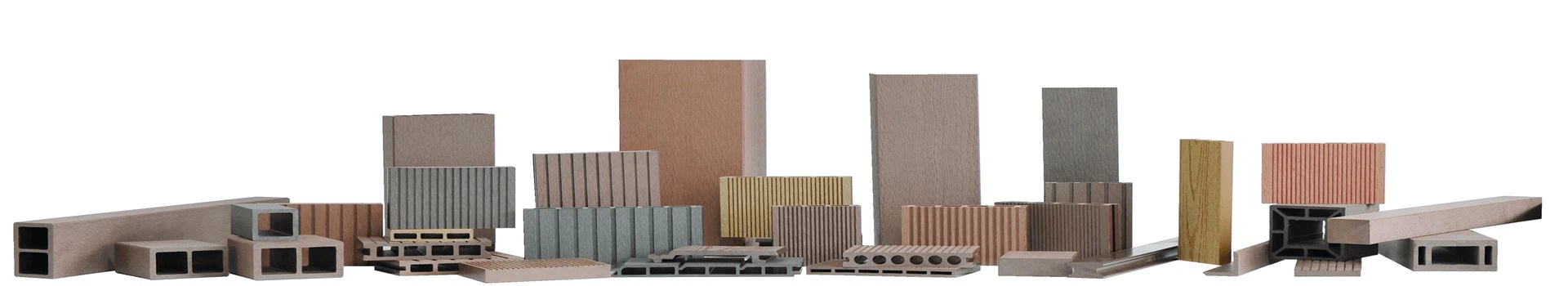

Understanding Composite Decking Materials

Compound decking products differ in make-up, with some including even more wood fiber while others might be predominantly plastic. This variant influences the type of saw blade you should use. Right here are a few considerations:

| Material Composition | Suggested Blade Type |

|---|---|

| High Wood Content | Carbide-Tipped Blades |

| High Plastic Content | Diamond Blades |

| Blended Composition | Multi-Purpose Blades |

Secret Features of Saw Blades for Composite Decking

When picking a saw blade for composite decking, think about the following trick functions:

- Tooth Count: A greater tooth count (40-60 teeth) can give smoother cuts, which is perfect for composite materials.

- Material: Carbide-tipped blades are suggested for their durability and efficiency against wear, specifically on timber fibers.

- Kerf Width: A thinner kerf can minimize material loss, making it much more efficient for reducing.

Usual Blade Types for Composite Decking

Here are a few of the most reliable blade types to think about:

- Framing Blades: Generally used for harsh cuts; guarantee they are carbide-tipped.

- Finish Blades: Designed for smooth cuts; perfect for visible edges.

- Specialty Blades: Diamond blades can be used for thick composite materials, lowering damaging and splintering.

Using a blade made especially for composite goods, in my experience not only increases cutting quality but also extends the lifetime of your equipment. The little financial outlay involved in choosing the finest saw blade pays out in performance and good quality for your decking projects.

Secret Features of Saw Blades for Composite Materials

When selecting a saw blade to cut composite outdoor decks, it's important to take several important factors into account that enhance performance and guarantee exact, neat cuts. Usually composed of a combination of plastic and wood fibers, compound materials have unique properties that need certain blades to get the best effects.

Tooth Design

Establishing precisely how well the saw blade performs with composite materials depends mostly on its tooth configuration. Blades designed especially for compounds with minimal tooth matter allow for quicker cutting and reduce the risk of breaking by themselves. Perfect is a tooth matter between 24 and 40 teeth because it strikes a compromise between the demand for speed and the need of neat sides.

Material Composition

An other vital factor is the blade's material structure. Especially indicated are blades made of high-speed steel (HSS) or those with carbide-tipped sides. Specifically helpful are carbide-tipped blades as they can withstand the abrasiveness of composite outdoor decking materials and prolong intensity.

Blade Thickness

Additionally affecting efficiency is the blade's thickness. For puncturing composite goods, thinner blades are more effective as they usually produce less waste and need less running power. Still, the density must be matched with the necessity for stiffness to prevent bending during cutting.

Kerf Width

Achieving the desired surface on composite decking depends on the kerf width of a blade, which determines its size of suffice. Preserving the integrity of composite outdoor decking sides depends on material loss being modest, hence a small kerf blade reduces splintering.

Cooling Features

Some saw blades contained cooling down features, including unique port layouts or coatings that distribute heat throughout lowering. For composite materials, which may produce significant warmth during the reduction process, this is particularly important. Using blades with cooling qualities helps prevent composite product deformation or melting.

Compatibility with Cutting Tools

Make sure the selected saw blade fits your cutting tool at last. The arbor dimension and blade size should meet the requirements of your gear whether you are using a table saw, round saw, or miter saw to guarantee dependable and safe technique.

Top Brands and Models of Saw Blades for Composite Decking

When selecting the best saw blade for composite outdoor decking, many reputable brand names catch interest because of their top quality, accuracy, and lifetime. Every brand guarantees neat cuts and extended blade life by including features meant to control the specific characteristics of composite materials. I have included below some of the top brand names along with suggested designs.

Leading Brands

1. DeWalt

DeWalt is recognized for its durable power devices and accessories, including saw blades specifically created for composite decking. Their blades commonly include:

- High-Quality Carbide Tips: For long-lasting sharpness.

- Slim Kerf Design: Minimizes worldly waste and supplies smoother cuts.

2. Freud

Freud blades are renowned for their outstanding efficiency. They use advanced modern technology in their production procedure, which causes:

- Laser-Cut Precision: Reduces vibration and noise during cutting.

- Specialized Tooth Geometry: Enhances reducing performance for composite materials.

3. Makita

Makita uses an array of saw blades enhanced for composite outdoor decking. Key features consist of:

- High Tooth Count: For cleaner cuts and decreased splintering.

- Resilient Coatings: To stand up to pitch accumulation from composite products.

4. Oshlun

Oshlun gives premium blades that are budget friendly yet reliable. Their saw blades are remarkable for:

- High-Grade Steel Construction: Ensures strength and toughness.

- Three-way Chip Grind (TCG) Tooth Design: Ideal for puncturing composite decking with marginal cracking.

Recommended Models

| Brand | Design | Diameter | Teeth Count | Special Features |

|---|---|---|---|---|

| DeWalt | DWA7810 | 10 inches | 60 | Thin kerf, carbide suggestions |

| Freud | LU91R010 | 10 inches | 80 | Laser-cut, anti-vibration |

| Makita | B-09600 | 10 inches | 80 | Durable layer, high tooth matter |

| Oshlun | SBNF-1000 | 10 inches | 40 | TCG design, top-quality steel |

When selecting a saw blade for composite decking, take into account the particular needs of your project including the kind of composite material and the intended finish. Any kind of outdoor decking job will benefit from the suitable blade as it not only improves performance but also extends the life-span of your gear.