1. Material Selection Guide: Matching Properties to Environments

| Environment | Composite Solution | Performance Benchmark |

| Coastal Zones | PVC Co-extruded Profiles | Salt spray resistance > 3,000 hrs |

| High Humidity | Antimicrobial wPC Decking | 0 mold growth |

| Extreme UV Exposure | Ti0, Photocatalytic Coating Panels | 99% UV reflectance |

2. Environment-driven material selection decision system

①.Corrosive environment requires molecular protection

Seaside area: While the seaside resort is enjoying beautiful scenery, if general equipment is not protected in advance, it is easy to become brittle or rot under the long-term attack of sea breeze and unshaded exposure.

Select PVC co-extruded composite materials with salt spray resistance > 3000 hours

Solve the problem: Balcony handrails have no rust marks for 15 years, eliminating the trouble of clothing contamination

②.High humidity environment requires biological resistance first

Rainforest hot spring: In the process of rainwater from steam to rainwater in the natural environment, a small amount of chemicals or dust in the air will often fall down together. Long-term immersion or scouring of rainwater on exposed building materials will inevitably breed bacteria.

Use mildew-proof WPC wood-plastic board

Solve the problem: No mildew residue when walking barefoot, and maintenance costs are reduced by 82%

③.Light energy management in strong sunshine areas

Desert landscape hotel: The characteristics of the desert environment are dry and hot, and the intensity of ultraviolet light is quite strong under the sun on the unshaded flat ground. If you want to live in the desert, the best solution is to fully equip the nano titanium dioxide coating plate with UV reflectivity ≥ 97%

Solution: The perceived temperature in the open-air dining area is reduced by 4-6℃, and the use of parasols is reduced by 50%

Instant Experience Layer

| Contact surface | User perception | Material technology support |

| Walking barefoot | warm touch (surface temperature <36℃ in summer) | Original ecological wood board |

| Handrail contact | no burrs and no temperature difference | WPC co-extrusion coating technology |

| Eye lighting needs | Soft path lighting without glare | GFRP diffuse reflection light guide structure |

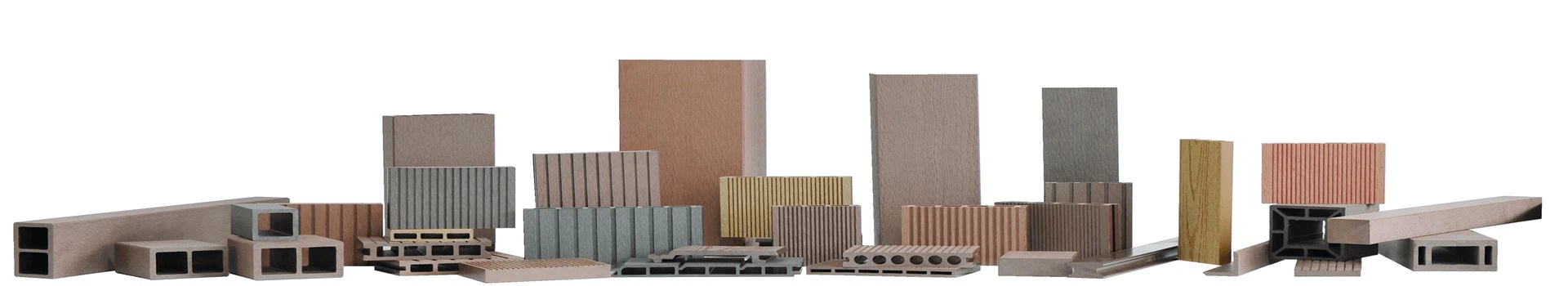

3.Composite materials are the core of material selection in resort decoration

1. Anti-slip paving system

The surface embossing process of wood-plastic composite materials (WPC) is adopted, and thermal expansion joints are reserved. The safety of wet and slippery areas such as swimming pools and terraces is significantly improved, and effective anti-slip is achieved throughout the year.

2. Translucent guide structure

GFRP translucent panels are selected in combination with embedded lighting systems, and waterproof lines are pre-buried. Ensure that the path guidance at night is glare-free and greatly reduce lighting energy consumption.

3. Special-shaped curved surface construction

Based on the one-piece molding technology of carbon fiber reinforced polymer (CFRP), complex shapes such as shell pavilions and streamlined landscape walls are realized, meeting the wind resistance requirements of more than level 12.

4. Multifunctional modular floor

The honeycomb aluminum-based composite panel is combined with snap-on splicing to support the rapid conversion of scenes such as dining areas and activity areas, and improve the efficiency of space use.

5. Intelligent temperature-controlled floor

The phase-change microcapsule composite floor material is linked to the temperature sensing system to ensure that the surface temperature of venues such as children's activity areas is at a safe threshold in summer.

6. Self-cleaning facade engineering

The nano-titanium dioxide coated composite panel is combined with the inclined installation process to achieve surface self-cleaning by natural precipitation and reduce the frequency of maintenance.

7. Weather-resistant edging treatment

PVC co-extruded composite materials are seamlessly coated by hot-melt, which completely solves the rust problem of metal components in coastal areas and prolongs the life of facilities.