Membrane Under Composite Cladding: Is It Necessary?

Are you asking, "Do I need a membrane under composite cladding?" This paper explores the principles of composite cladding and the crucial part a membrane plays improving its performance. From moisture control to better insulation, find out why using a membrane may transform your construction projects.

Benefits of Using a Membrane

We will discuss the advantages of a membrane, the considerations to make when selecting one, and the typical errors to prevent during installation. By the time this essay ends, you will have a thorough grasp of the reasons a membrane is absolutely essential for optimizing the lifetime and performance of composite cladding.

What is Composite Cladding?

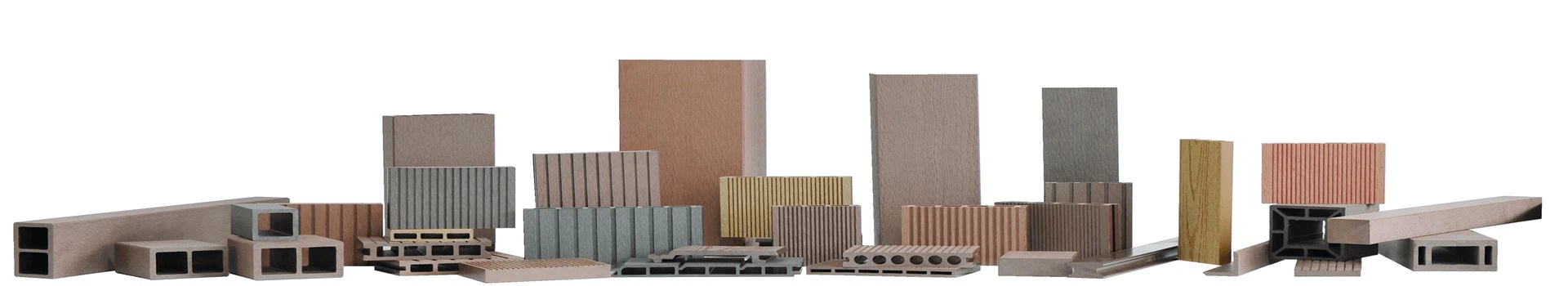

Modern construction materials that combine the benefits of plastic and wood to create an extremely strong and visually beautiful outside covering for buildings are composite cladding. Architects and builders especially like this material as it is designed to be low-maintenance and long-lasting alternative to ordinary wood cladding.

Trick Components of Composite Cladding

Composite cladding generally contains the adhering to parts:

| Component | Summary |

|---|---|

| Timber Fibers | Give natural appearance and texture |

| Plastic (normally PVC or HDPE) | Enhances sturdiness and resistance to wetness |

| Binders and Additives | Improve strength, UV resistance, and color security |

Benefits of Composite Cladding

- Compound cladding deals several advantages over traditional products, consisting of:

- Durability: Resistant to rot, degeneration, and bug damages.

- Low Maintenance: Requires very little maintenance compared to wood.

- Aesthetic Appeal: Available in a range of shades and surfaces.

- Ecological Benefits: Often made from recycled materials.

Applications of Composite Cladding

Composite cladding is functional and can be utilized in various applications:

- Residential homes

- Industrial structures

- Public structures

- Renovation projects

Making informed decisions on the use of composite cladding depends on an awareness of its structure and benefits. This makes one wonder: "Do I need a membrane layer under composite cladding?" The answer to this question depends on several factors, which we shall discuss in the next sections.

Advantages of Using a Membrane Under Composite Cladding

Boosted Moisture Protection

Using a membrane layer beneath composite cladding has many advantages mostly related to its ability to provide improved moisture control. Although strong, composite cladding may nevertheless be vulnerable to moisture seepage particularly in areas with plenty of moisture or regular precipitation. An extra barrier is a membrane, which prevents water from seeping through the construction and starts possible harm like mildew, rot, or mold.

Improved Insulation and Energy Efficiency

The increase in insulation and power performance adds even another major benefit. By helping to create an additional airtight seal, a membrane layer reduces drafts and heat loss. Reduced energy expenses and a far more pleasant living environment follow from this. The membrane layer may also help the structure's total thermal performance by acting as extra layer of insulation.

Prolonged Lifespan of the Cladding

Furthermore extending the lifetime of the composite cladding is possible by using a membrane. The membrane helps to preserve the integrity and appearance of the cladding over time by resisting moisture and many other environmental factors. Less repair services and replacements resulting from this will naturally save money and time down-stream.

Boosted Structural Integrity

beneath composite cladding, including a membrane layer beneath increases architectural stability of the construction. The membrane layer may assist to distribute loads more fairly and guard against water damage or other issues compromising the concealed structure. In places likely to have extreme climatic issues, this extra layer of protection may be very helpful.

Enhanced Property Value

Last but not least, applying a membrane may increase the whole value of the house. Usually, potential consumers search for houses with strong, premium building materials. Knowing that a membrane layer has been installed beneath the composite cladding may be a marketing tool, implying that the construction has been created with interest for long-lasting efficiency and knowledge in mind.

Factors to Consider When Choosing a Membrane

Material Compatibility

It's important to make sure the membrane layer product fits the composite cladding material when selecting one for usage beneath it. Incompatible materials compromise the integrity of the cladding system by causing chemical reactions or over time degradation.

Waterproofing and Breathability

Among the main purposes of a membrane beneath composite cladding is to provide waterproofing and for the structure to breathe. Choosing a membrane that offers a high degree of waterproofing will help to restrict water access by means of which moisture vapor may escape, therefore preventing mold and mildew development.

Resilience and Longevity

Two very important considerations are the membrane's lifetime and strength. The layer of membrane must be able to withstand mechanical stress, temperature fluctuations, UV direct exposure, and other environmental challenges. Long-term performance of the composite cladding system is guaranteed by a strong membrane.

Installment Ease

One additional important factor is relieving of installation. Easy installation of a membrane layer helps to reduce labor costs and time. Seek for membranes meant to be simple and with clear setup rules.

Cost-Effectiveness

Although a premium membrane layer is desirable, one should also take cost-effectiveness of the item into great account. To ensure you are getting the most value for your financial outlay, evaluate the performance of the membrane layer loved one against its cost.

Environmental Impact

Consider how the membrane material affects the surroundings. Select environmentally friendly, recyclable, or constructed from durable goods membranes. This not only helps to reduce the carbon footprint but also straightens with new architectural guidelines and rules.

| Variable | Value |

|---|---|

| Product Compatibility | Stops chain reactions and degradation |

| Waterproofing and Breathability | Avoids water access and permits moisture vapor escape |

| Sturdiness and Longevity | Ensures long-lasting performance |

| Setup Ease | Saves time and labor prices |

| Cost-Effectiveness | Provides ideal worth for financial investment |

| Environmental Impact | Decreases carbon footprint |

Installment Process: Membrane Under Composite Cladding

Preparation

Making sure the surface area where the composite cladding will be put is neat, totally dry, and free of any form of particles is very important before beginning the installation process. This will help to produce a flawless and safe installation. Moreover, gather all necessary tools and supplies: the layer of membrane, glue, and composite cladding panels.

Choosing the Right Membrane

The durability and efficiency of the cladding system depend on the choice of appropriate membrane. Look for water-resistant, breathable membrane layers that fit the specific kind of composite cladding being used. To withstand environmental anxiety, the membrane layer must also be very tensile tough and UV ray resistant.

Cutting and Positioning the Membrane

Step the dimensions of the site to be covered and cut the membrane layer suitingly. Guarantee that, at least six inches of overlap between the membrane layer parts prevent any kind of water seepage. Starting with all-time low and working your approach, arrange the membrane layer on the substrate. This will help to channel water away from the construction site.

Safeguarding the Membrane

Protect the membrane layer by using suitable bolts or glue after it is situated correctly. Make sure the overlaps and sides are tightly closed to prevent any gaps. Pay particular attention to joints, sides, and corners as these places are much more prone to water penetration.

Installing the Composite Cladding

The installation of the composite cladding panels may start after the membrane is securely in place. Link the cladding to the substrate according to manufacturer guidelines. Make sure the panels are degree and regularly spaced; use the recommended fasteners to protect them. Verify if the cladding is suitably straightened and whether any misalignments or gaps exist.

Final Inspection

When the installation is complete, carefully evaluate to ensure the composite cladding and membrane are put up correctly. Search for any clues of exposed regions, misalignments, or gaps. Addressing any issues right away guarantees the cladding system's integrity and effectiveness.

Common Mistakes to Avoid When Installing a Membrane

Improper Surface Preparation

Among the most common mistakes made while laying a membrane layer beneath composite cladding is neglecting suitable surface area preparation. The membrane layer depends on a clean, totally dry, cost-free surface area devoid of any kind of waste to stick correctly. Stopping working to do so could lead to poor attachment, therefore compromising the membrane's performance.

Inadequate Overlapping

Another regular mistake is not giving sufficient overlapping in between membrane sheets. Overlapping is vital to stop water seepage. The recommended overlap normally ranges from 6 to 12 inches, depending upon the supplier's standards.

| Overlap Type | Suggested Overlap |

|---|---|

| Straight Overlap | 6-8 inches |

| Upright Overlap | 10-12 inches |

Incorrect Fastening

Another often occurring problem is improper membrane layer adhesion. Using the incorrect kind or insufficient variation of fasteners might cause membrane layer displacement in time. Following manufacturer standards for bolt type and spacing is essential to ensure the membrane stays in safe alignment.

Disregarding Weather Conditions

The installation procedure depends much on climate condition. Mounting a membrane in moist or very cold situations might affect its performance. To ensure perfect bond and performance, it is advised to review weather forecasts and get ready the setup in a good climatic state.

Stopping Working to Seal Penetrations

Potential powerlessness wherein water may enter vents, pipelines, and residential windows is known as infiltration. Ignorance of appropriate security for these infiltrations may compromise the overall layer structure of membranes. Use flashing and suitable sealants to guarantee any infiltrations are suitably sealed.

Not Following Manufacturer's Guidelines

Every membrane layer product has specific manufacturer installers. Ignoring these guidelines could lead to incorrect arrangement and less efficiency. Refer to the supplier's guidelines constantly and follow their recommendations to be sure the membrane layer runs as expected.